INDUSTRY APPLICATION

Common industrial modes of wear addressed with our coatings

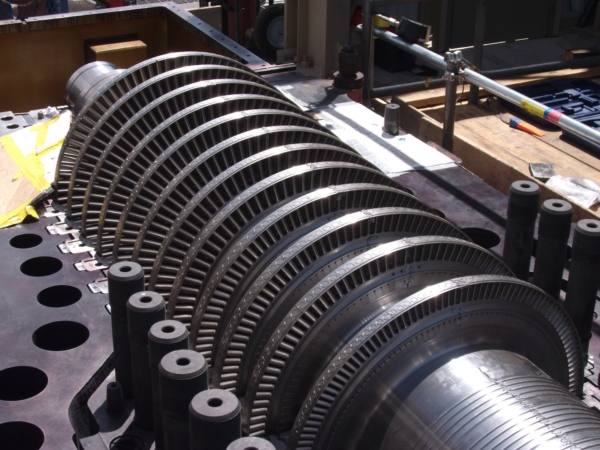

- Abrasion-Wear caused from two parts rubbing against each other.

- Erosion-Wear due to impact for gas, liquid, solid particle or combination.

- Adhesion – Occurs when solid surfaces slide over each other under pressure. Also known as galling.

- Corrosion-Breakdown due to chemical reaction with environment.

QUALITY COATINGS

Our coatings are used to extend the life of your parts by properly addressing and resisting wear

“Trinity Coatings provides quality in all aspects to meet our coating requirements. Their attention to detail in all phases is second to none. Coatings you can count on at competitive cost and lead times”

“Believe me if there is anything Trinity in general can do for us, it will be sent there. Always happy with everything from you guys.”

“Trinity Coatings has exceeded our expectations and significantly increased quality while improving our deliveries. We could not have picked a better partner.”