Project Description

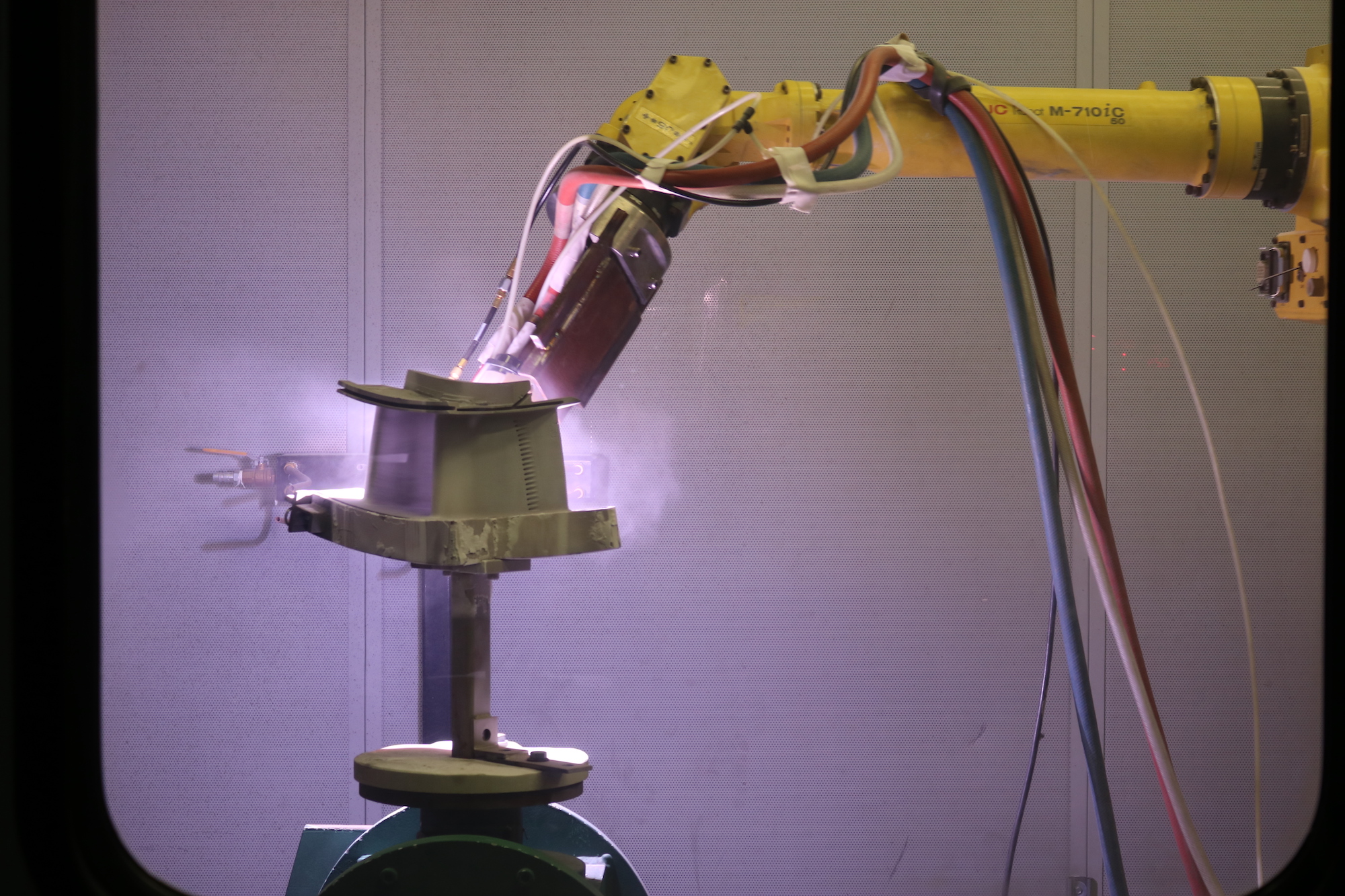

Air Plasma Spray – APS Coatings

- Thermal Barrier Coatings

-

- Thermal Barrier Coatings are used on air cooling gas turbine components to reduce the temperatures of the metal substrate. The coatings consist of a MCrAlY bond coat and yttria-stabilized zirconia top coat. The lower thermal conductivity, low k, of TBC is produced by a porous zirconia topcoat. This ceramic insulates the substrate for the hot gas. The exact temperature gradient provided by the insulating TBC is difficult to calculate because it dependent on several external factors such as the amount and temperature of the cooling air to the part. It can be estimated that the TBC lowers substrate temperature by about 10 degree F per mil of TBC. So 15 mils of TBC will reduce substrate temperature by about 150 degrees F.

-

- MCrAIY Coatings

-

- MCrAlY (pronounced ‘emcrawlee’) coatings are overlay coatings that combine metal ‘M’ with chrome ‘Cr’, aluminum ‘Al’ and yttrium ‘Y’ (stabilizer). The metal is usually nickel, cobalt or a combination of nickel and cobalt. Yttrium helps stabilize the oxide scale that is formed during service. APS MCrAlY coatings provide adequate roughness to serve as a bond coat of the TBC coatings. Often APS MCrAlY coatings are used as flash or intermediate coat to provide roughness when HVOF MCrAlY’s are applied.

-

- Abradable Coatings

-

- APS abradable coatings are specifically designed to reduce clearances between the rotating and stationary components in a gas turbine. The abradable coatings increase the efficiency of the gas turbine and help protect the components for damage if a rub occurs. The abradable coating are designed to sacrificially wear is such rub occurs. Abradable coatings are used in both the compressor and turbine section. Typical applications for abradable coatings are compressor blade rings, labyrinth seals, ring segments, shroud blocks, and tip shoes. The abradable coatings are a variety of materials depending on application. Some abradable are made using softer material such as aluminum or graphite and higher temperature abradable are produced by creating high porosity MCrAlY and TBC.

-

- Dimensional Restoration

-

- All forms of wear remove material. Coatings can be used to reproduce the missing material and reduce wear. These coatings are referred to as dimensional restoration coatings.

-

- Hard Facing Coatings

-

- Hard facing coatings are coating used to protect substrate from erosive abrasive, and adhesive wear. The coatings are dense and typically much harder than the substrate of the component that they are used to protect. These coatings often contain carbides.

-