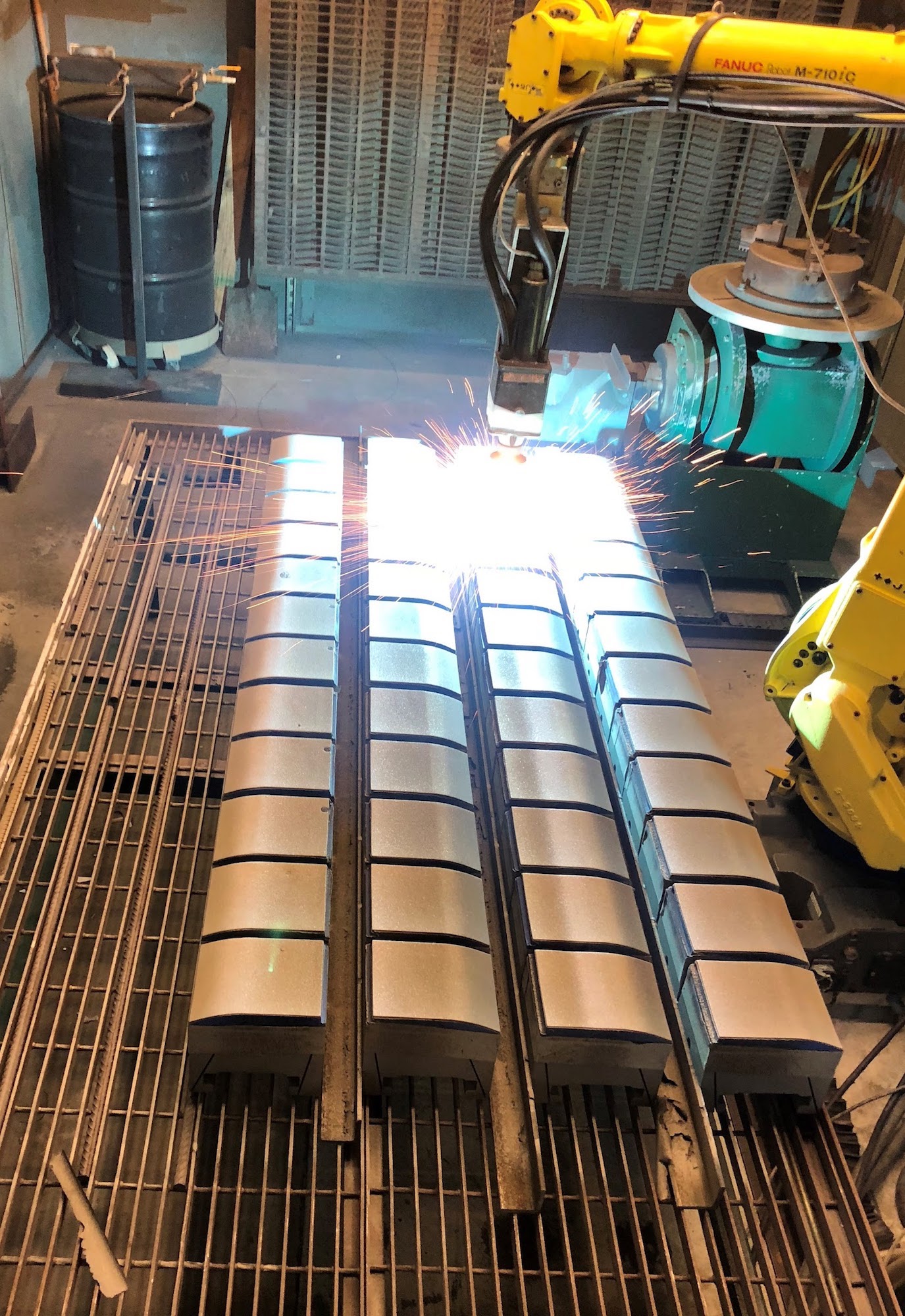

Arc Wire Spray

admin

2018-10-26T14:28:37+00:00

Project Description

Arc Wire Spray

- Dimensional Restoration

-

- All forms of wear eventually remove material. Coatings can be used to reproduce the missing material and reduce wear. These coatings are referred to as dimensional restoration coatings. Arc wire coatings can successfully be applied much thicker than HVOF or APS coatings. Arc wire coatings have high bond strengths.

- Inconel®

-

- Inconel coatings are nickel chromium based coatings known for their for oxidation, corrosion and wear resistance. Common coatings are Inconel 625® and Inconel 718®

- Nickel & Aluminum

-

- Nickel & Aluminum coatings are excellent for material build and as bond coat for other materials. Ni/Al 95/5 and 80/20 are most common.

- Thermal-Sprayed Aluminum (TSA)

-

- TSA coatings provide excellent corrosion resistance. They are commonly used in subsea and offshore applications that demand the most for corrosion resistant coatings. The aluminum provides galvanic protection by acting as a sacrificial anode to protect the base metal.