Project Description

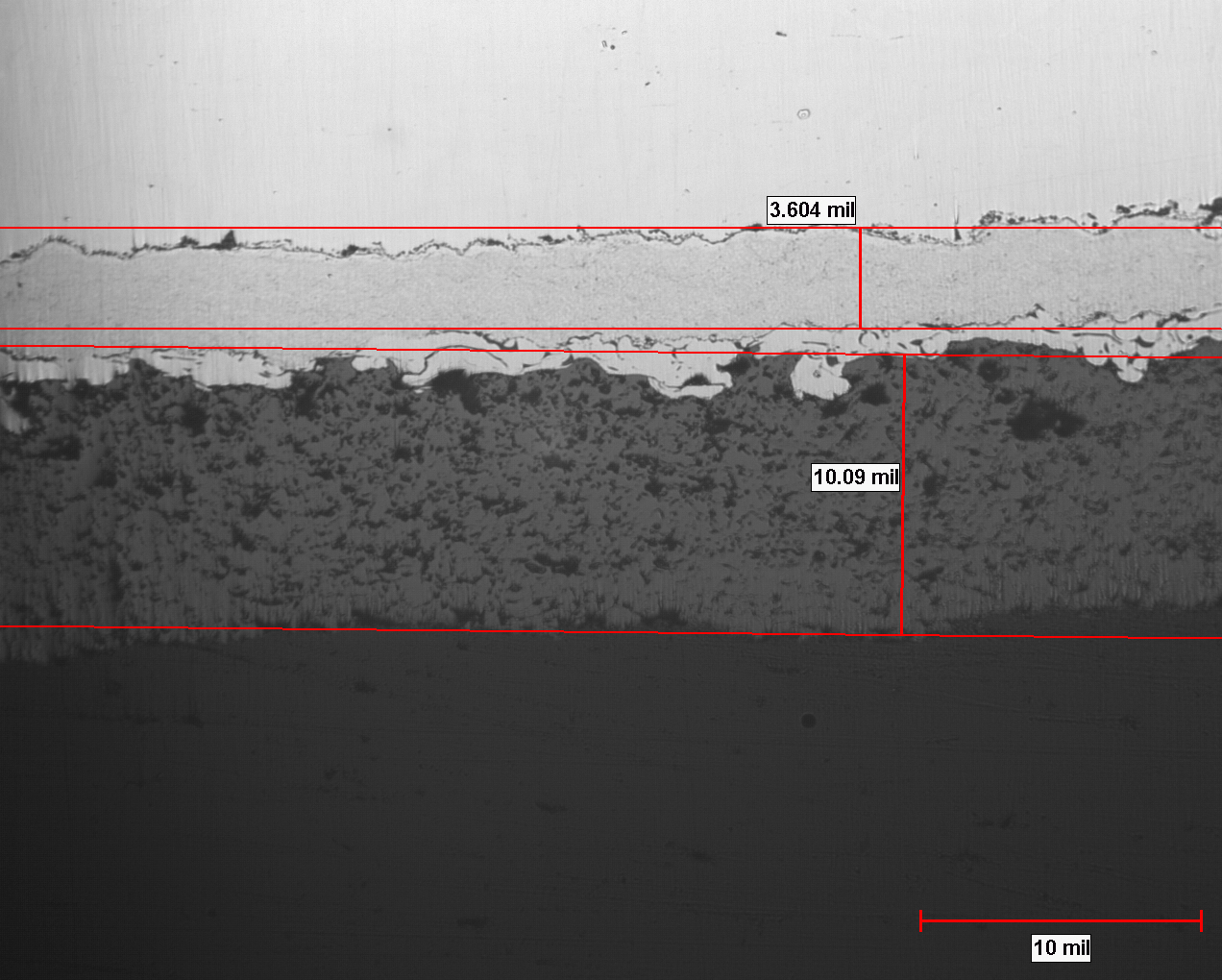

- Metallurgical Testing Lab – Trinity Coatings, LLC has mounting, polishing, and optical image analysis in-house to speed up the program qualification processes and prove the finished products.

- Hot Mounting Presses – Mount samples in epoxy and phenolic resins in minutes

- Vacuum Mounting – The vacuum chamber draws the epoxy in pores of coating. Allows proper porosity content measurement of TBC coatings and prevents damages to other brittle coatings.

- Automated Polishing –Removes human factor for repeatable results

- Optical Microscope with Image Analysis – Up to 500X magnification with optional automated porosity, oxide, and contamination measurements.

- Engineering

- Failure Analysis – Do you have a coating failure? Let Trinity Coatings, LLC review to determine the issues causing your failure. Issues could be contamination, improper surface preparation, or poor coating structure. Trinity Coatings, LLC can vacuum mount a small piece and review at a microscopic level.

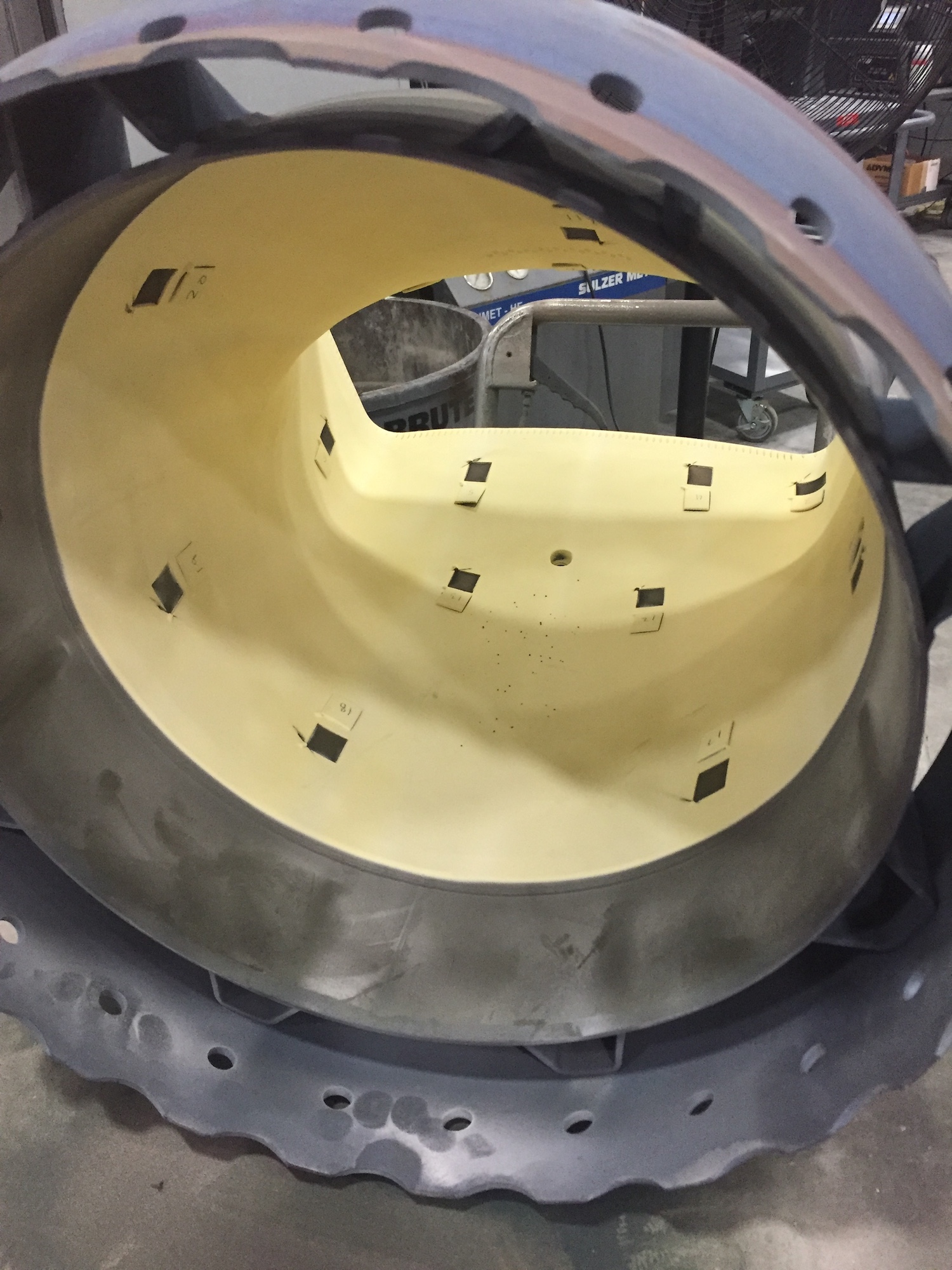

- Coating Development – All robotic programs include metallurgical lab testing.

- Coating Recommendations – Review and recommend a customized solution to extend the life of your parts.