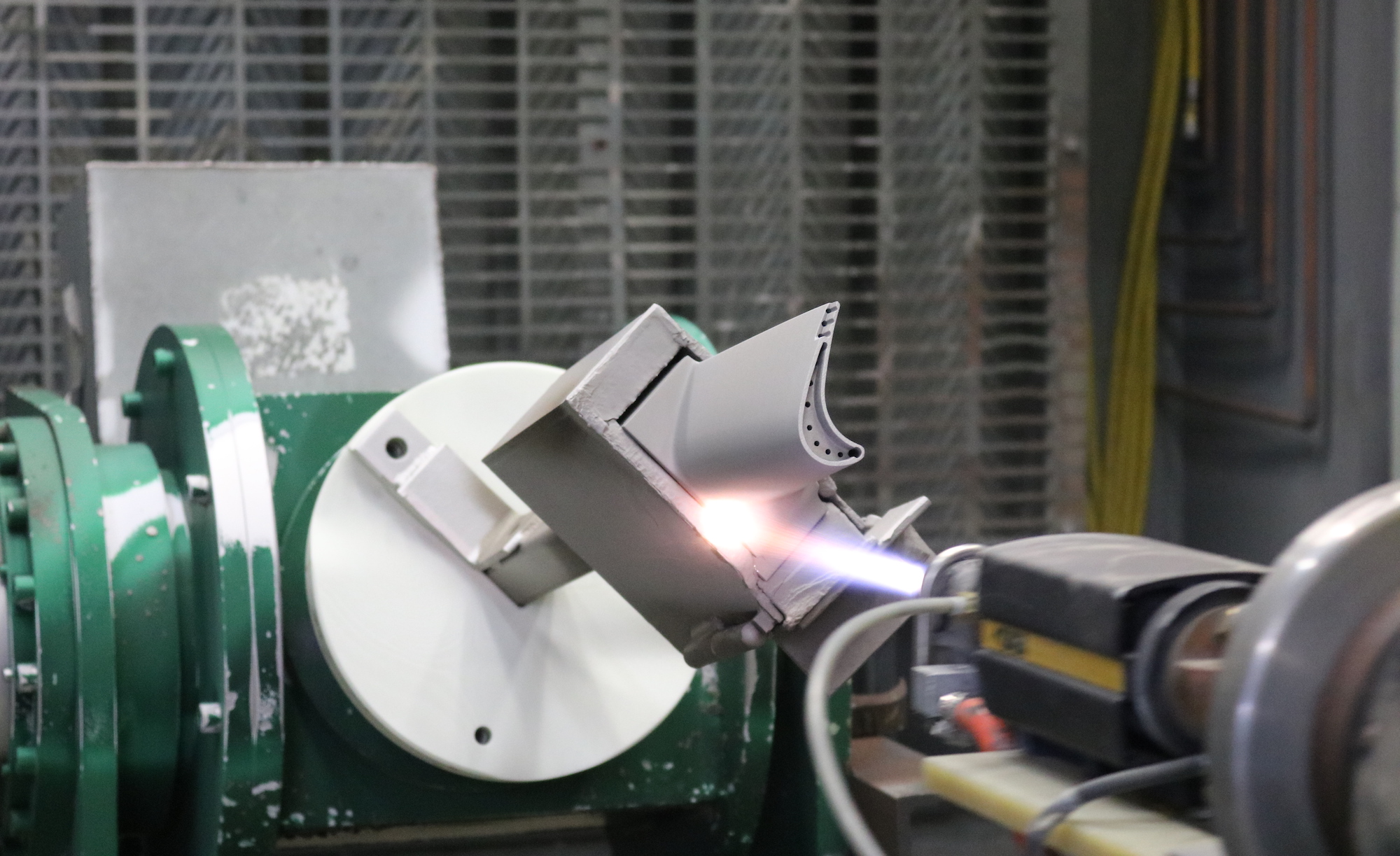

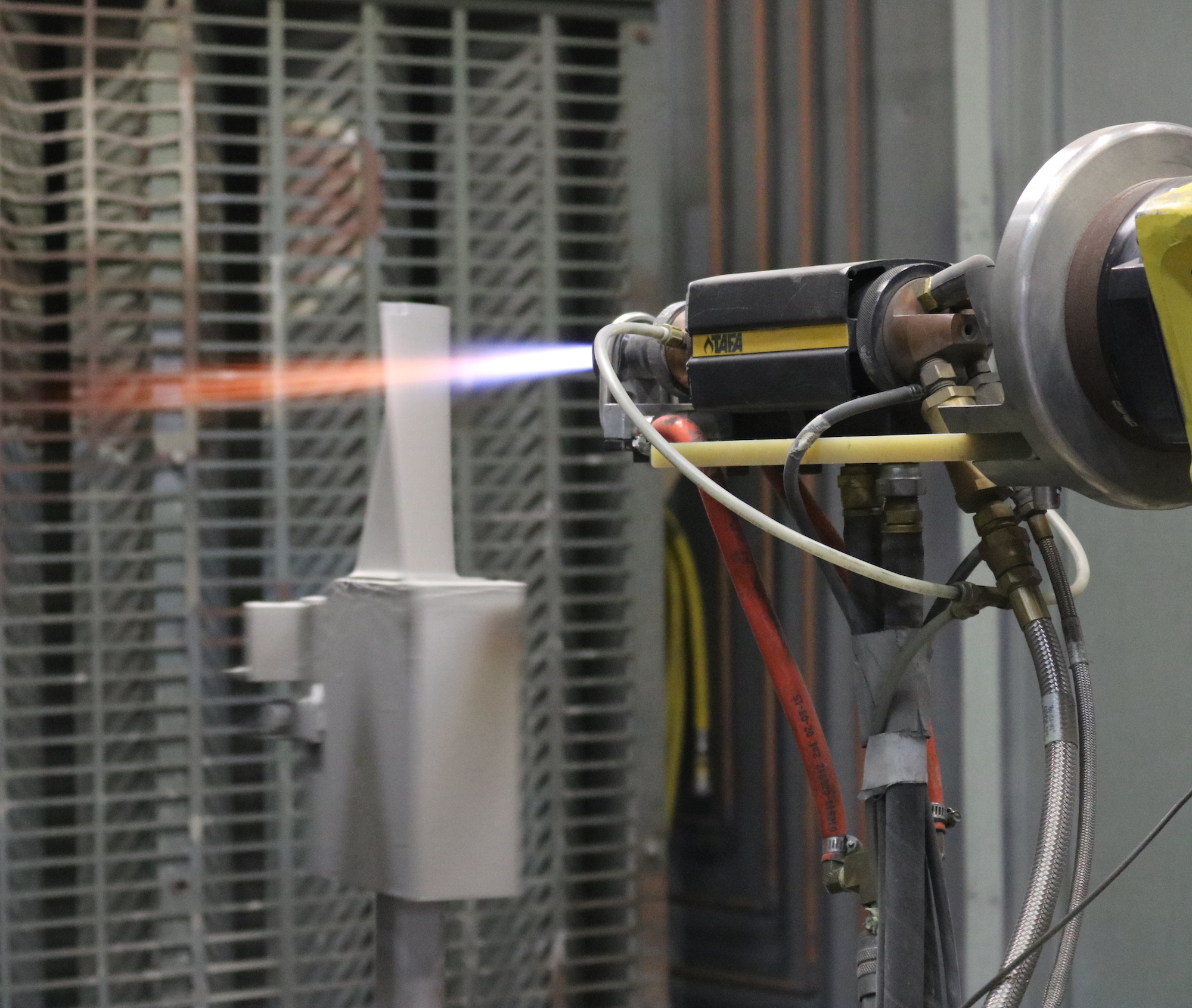

High Velocity Oxy-Fueled- HVOF

admin

2018-10-26T14:24:18+00:00

Project Description

HVOF

- MCrAIY coatings

-

- MCrAlY (pronounced ‘emcrawlee’) coatings are overlay coatings that combine metal ‘M’ with chrome ‘Cr’, aluminum ‘Al’ and yttrium ‘Y’ (stabilizer). The metal is usually nickel, cobalt or a combination of nickel and cobalt. Yttrium helps stabilize the oxide scale that is formed during service. HVOF MCrAlY coatings are much denser than APS coatings and have much higher bond strengths. HVOF MCrAlY coatings provide excellent oxidation and hot corrosion resistance. HVOF MCrAlY is the standard for gas turbine blades and vanes out performing diffusion coatings.

- Carbides

-

- Chromium carbide and tungsten carbide coatings are widely used for wear resistance. Chromium carbide has replaced had chrome plating with better performance and reduced safety and environmental concerns for hexavalent chrome. Tungsten carbide is even harder and often outperformed chrome carbides but has lower maximum temperature ratings.

- Hard Facing Coatings

-

- Hard facing coatings are coating used to protect substrate from erosive abrasive, and adhesive wear. These include the carbide coatings mentioned above. Other common hard face coatings are cobalt based such as Stellite® and Tribaloy® coatings. Common cobalt hard face coatings are Stellite 6 ®, Tribaloy T-400 ®, and Tribaloy T-800 ®.

- Inconel

-

- Inconel coatings are nickel chromium based coatings known for their for oxidation, corrosion and wear resistance. Common coatings are Inconel 625® and Inconel 718®